ENERGY PERFORMANCE: VINYL WINDOWS & DOORS

Continuous commitment to environmental conservation and energy efficiency are key ingredients in our product offering. We work toward this goal by partnering with ENERGY STAR® and offering packages that increase the energy efficiency and performance of all our products. Environmental awareness is at the forefront of our work from design to the innovative creation of manufacturing practices which are aligned with our core values.

ENERGY STAR® is the government-backed symbol for energy efficiency, providing simple, credible, and unbiased information that consumers and businesses rely on to make well-informed decisions. energystar.gov

The National Fenestration Rating Council is a non-profit organization that establishes objective window, door, and skylight energy performance ratings to help you compare products and make informed purchase decisions. nfrc.org

The National Fenestration Rating Council is a non-profit organization that establishes objective window, door, and skylight energy performance ratings to help you compare products and make informed purchase decisions. nfrc.org

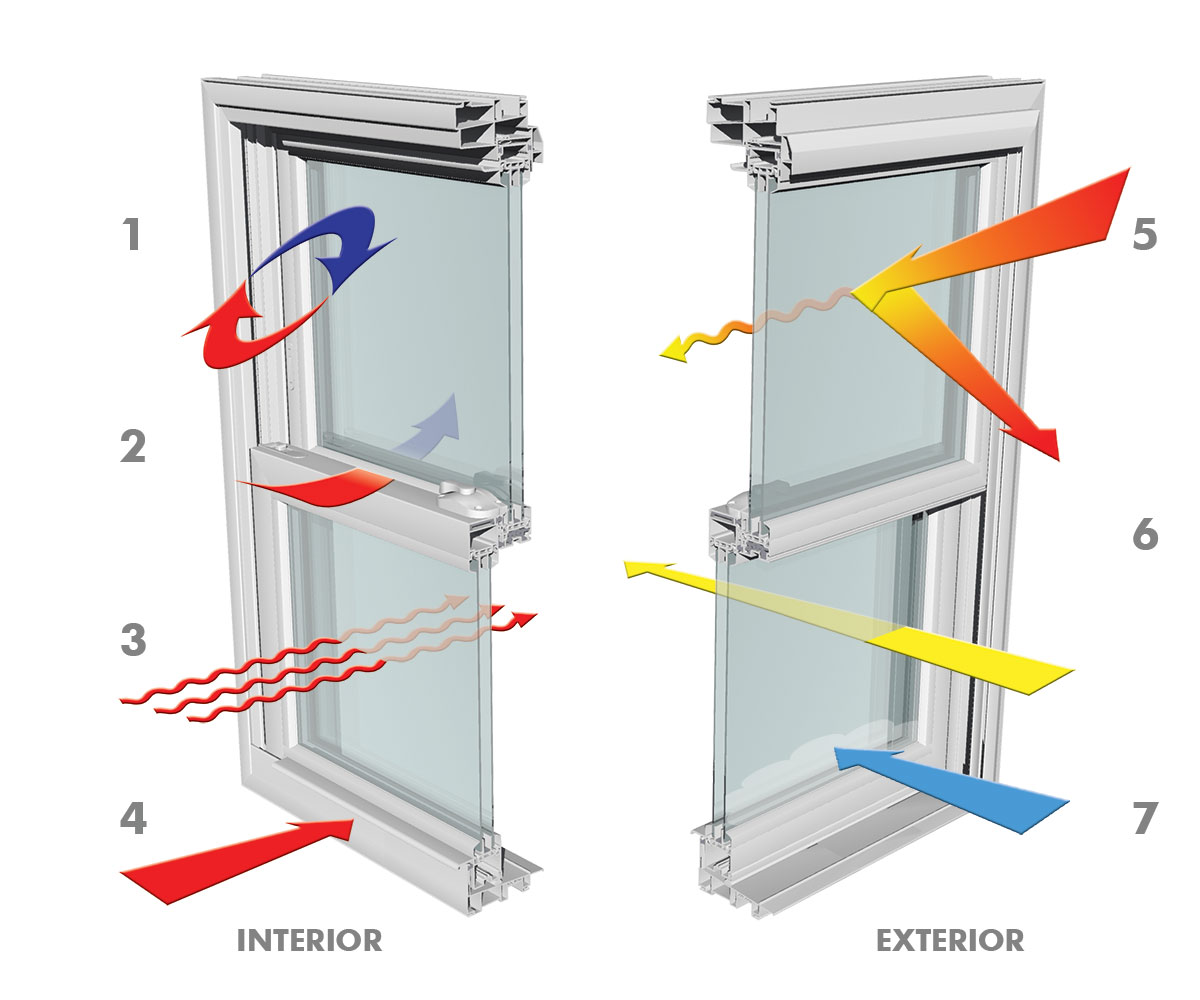

Our performance packages feature the latest and most innovative energy-efficiency technologies and respond to the following:

1 CONVECTION - Warm inside air meets a cold window, creating a chilly, circulatory. Performance Package windows can help reduce convection related problems.

1 CONVECTION - Warm inside air meets a cold window, creating a chilly, circulatory. Performance Package windows can help reduce convection related problems.

2 AIR INFILTRATION - Air leakage through unsealed gaps can account for up to 10% of the energy usage in a home. Performance Package windows offer premium airflow protection.

3 RADIANT HEAT LOSS - Clear glass absorbs interior heat and radiates it outdoors. Low-E glass coatings greatly reduce radiant heat loss, saving you money in the winter.

4 CONDUCTION - The direct transfer of heat through the window frame. Performance Package windows reduce thermal heat loss due to conduction.

5 SOLAR RADIATION - In the summer, solar radiation can dramatically increase cooling costs. In addition, UV radiation can fade and damage interior furnishings. Performance Package windows feature a Low-E coating that greatly reduces solar radiation and provides superior UV protection.

6 LIGHT TRANSMITTANCE - Low-E coatings allow short wave visible light to be absorbed through the window, which reduces lighting costs throughout the year and is reradiated as heat in the winter.

7 CONDENSATION - Condensation can damage window frames, sills, and interior shades while contributing to mold and indoor humidity. Northeast offers warm-edge spacers for superior condensation resistance.

Thermal Transmittance and Resistance (U and R-Values)

The higher the R-value of a window, the greater its insulating properties, and thus the greater its energy efficiency. Camelot® R-5 Ultra Performance Package windows feature one of the highest double=glazed R-values in the industry, for the ultimate in energy-efficiency and thermal performance.